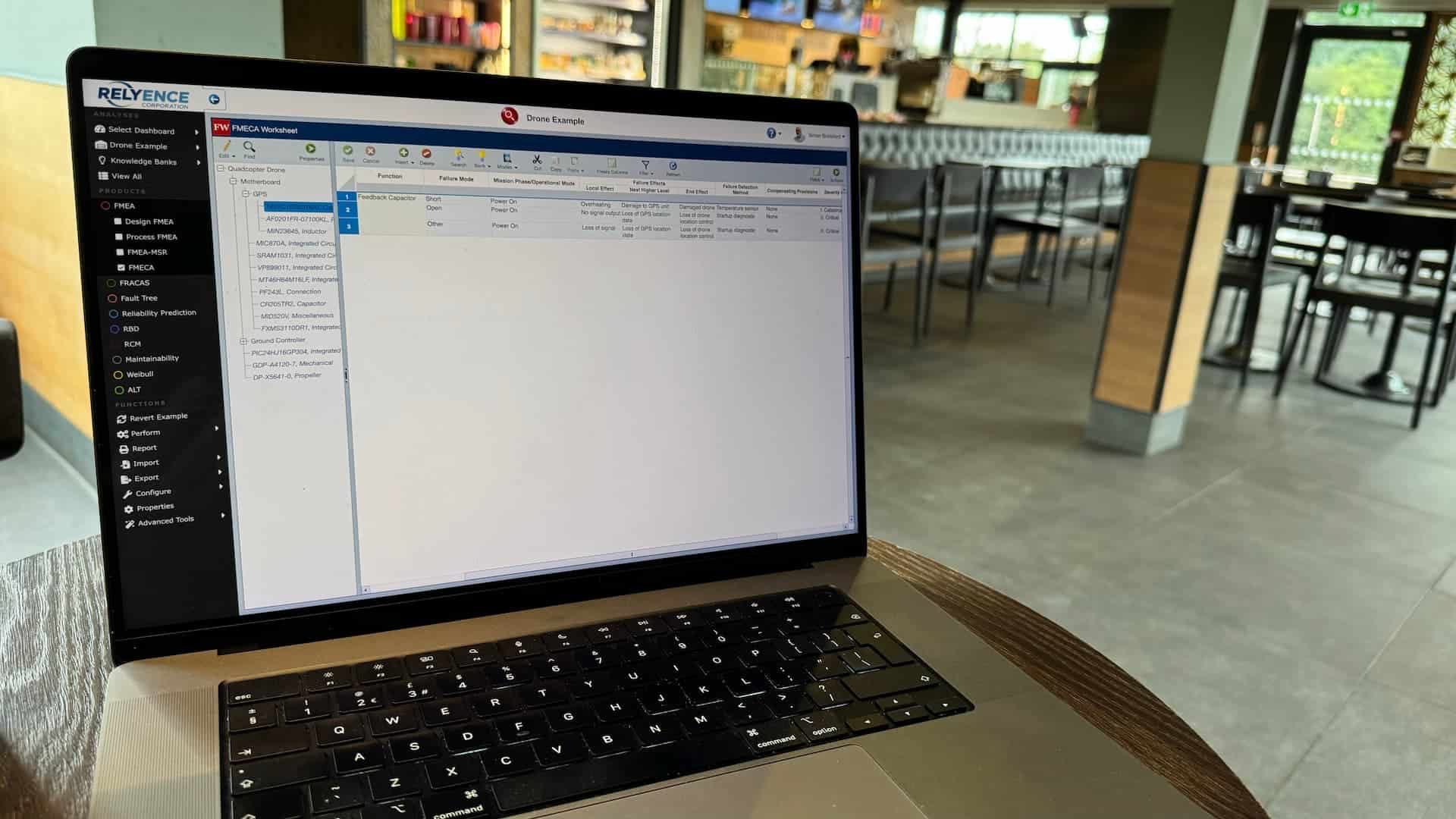

Failure Mode Effects & Criticality Analysis

Relyence

Nothing to download or install

Instant access, free web based trial

Relyence FMECA key features

As a fully integrated platform Relyence offers numerous key features that are shared across various modules, as and where applicable. Here's a small selection supported by the FMECA module however, check out the feature section for a full breakdown and to learn more.

Failure Direct Connect

Relyence Failure Direct Connect: Bridging FRACAS and FMEA for Continuous Improvement

Relyence Failure Direct Connect seamlessly integrates your DFMEAs, PFMEAs & FMECAs with your FRACAS data, providing valuable insights into the failure mechanism. By linking real-world failure data directly to your FMEA, Relyence closes the loop between your warranty returns and future design iterations.

One standout feature is the ability for users to suggest FMEA updates directly from FRACAS entries. This ensures that new issues are promptly incorporated into your FMEA, keeping your analysis current and comprehensive. The result? Enhanced collaboration, faster response times, and a powerful feedback loop that drives ongoing product reliability improvements.

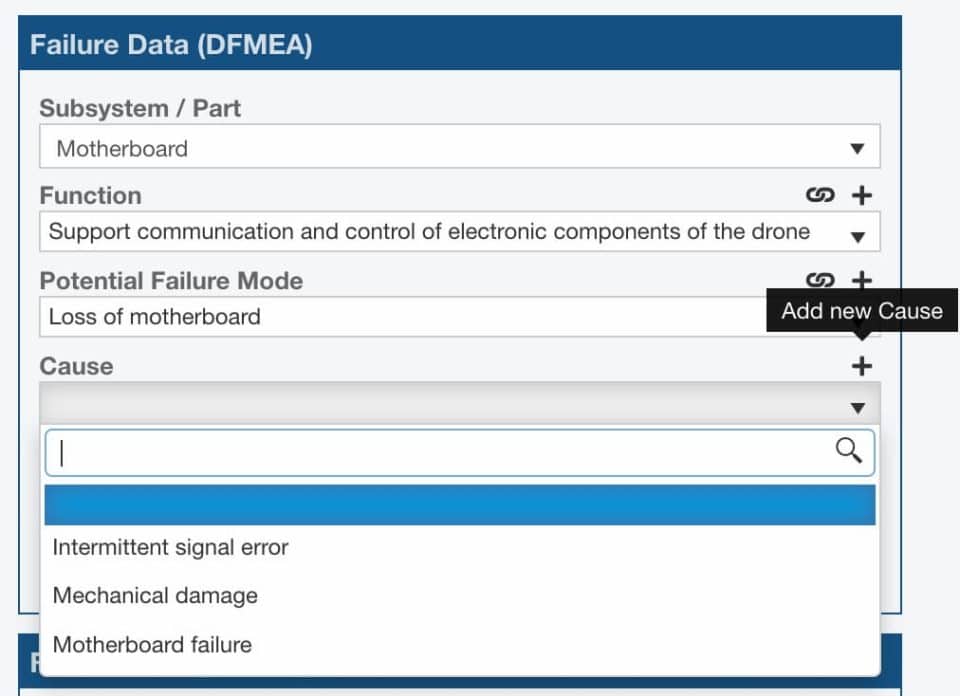

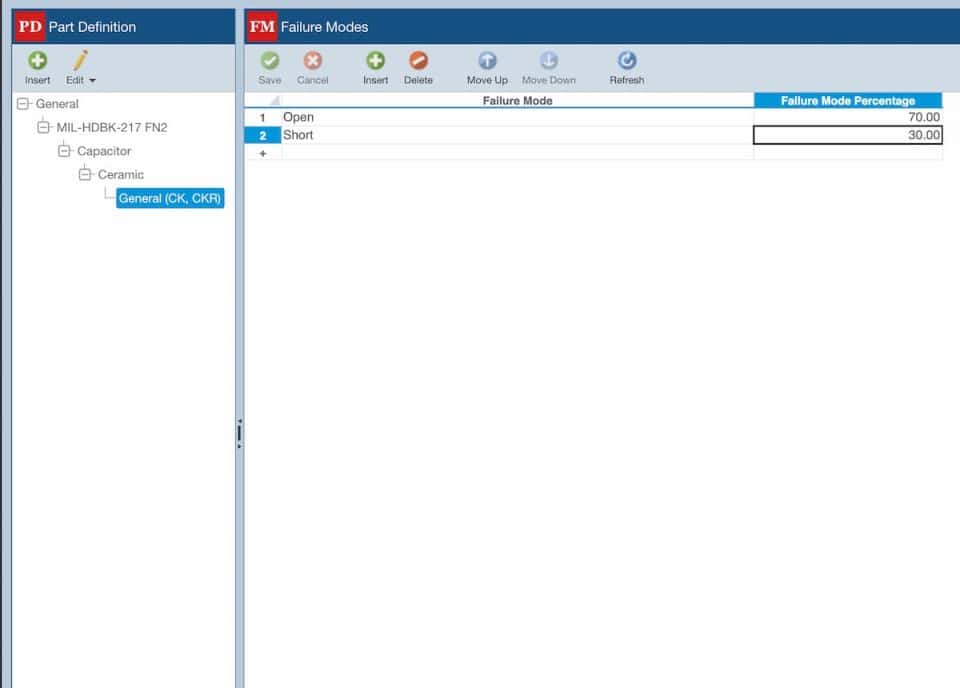

Custom Failure Mode Libraries

Custom FMEA Mode Library: Standardised, Efficient, and Tailored for Your Needs

The Custom FMEA Mode Library introduces a powerful way to streamline your piece-part DFMEA and FMECA processes. By creating a centralised repository of predefined failure modes and associated percentages for each part type, this feature ensures standardisation and consistency across your entire organisation.

Engineers no longer need to start from scratch for every analysis. Instead, they can leverage a comprehensive, predefined set of failure modes, accelerating the FMECA process and reducing the risk of missing critical issues.

The integration with Relyence Reliability Prediction also allows for a quick startup, pulling in relevant data when importing a Bill of Materials (BOM).

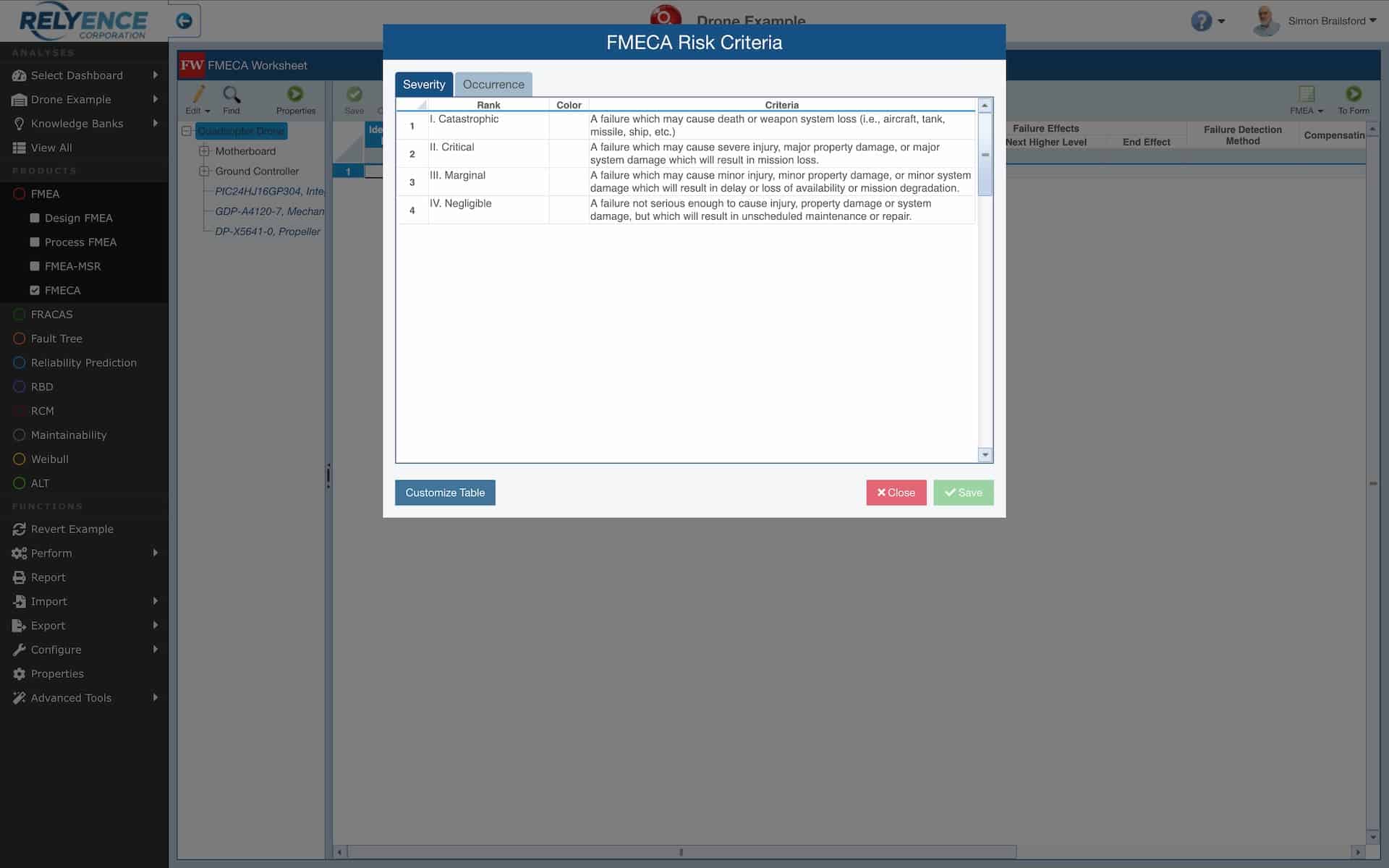

Relyence FMECA Core Features

As part of a fully integrated suite the Relyence FMECA module shares many core features with our other modules, saving your users time whilst providing for a more detailed analysis.

Our FMECA module shares data with the following Relyence products

Relyence FMECA Integrations

RCM

Streamline your maintenance strategies with our advanced RCM software, designed to optimize reliability and operational efficiency, crucial for Aerospace, Automotive, Electronics, and Medical Devices industries.

Relyence FMECA... is it the right choice for you?

Next Steps

Register for our free, no obligation web based trial.

No credit/debit card required, nothing to download/install.

or book a Zoom/Teams demo to find out more.